Attention!

Don't Turn Off The Fan!

Wear A Jacket & A Toque

We are noticing more and more that staff and managers are shutting off the blower fan (evaporator fan) when they are in the walk-in beer fridge.

I understand that when you are doing inventory that you can be in there for a while and it gets cold. But put on a jacket and a toque because it is creating problems for you and your bar.

Three Reasons Why You Must Stop Turning Off The Beer Fridge Fan:

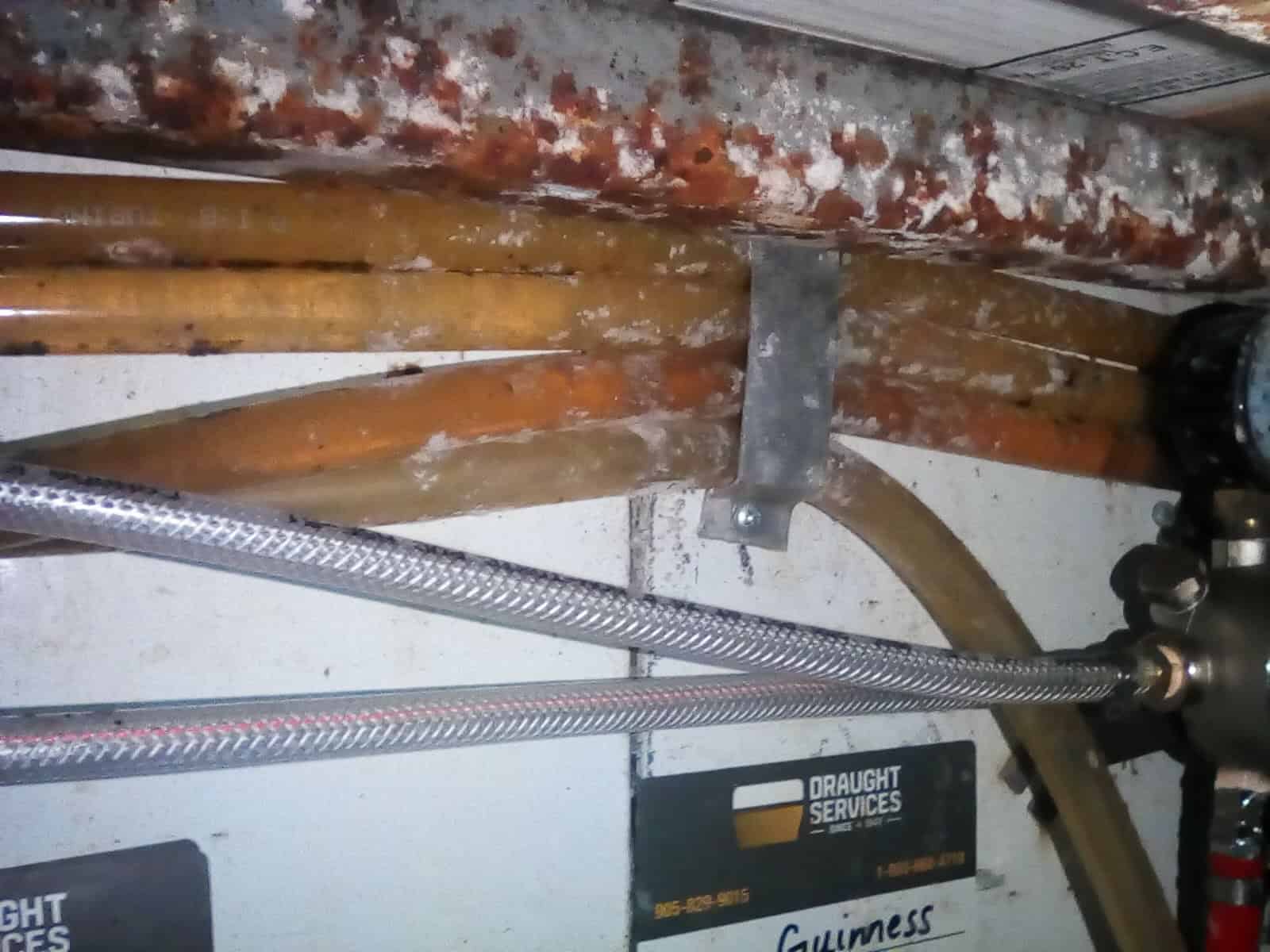

Reason #1 - Warm air enters the walk-in and causes any exposed cold lines to sweat. It is the humidity in the air quickly cooling on the cold equipment and lines which causes this condensation.

This condensation will freeze if the lines and equipment (usually Freon or glycol lines and fittings) are below 32F/0C, which they usually are.

This ice build up then melts the next time the door is open and it continues through this freeze-thaw cycle.

This freeze-thaw cycle eventuality wears down the insulation and you get wet insulation which starts to freeze and develops substantial ice build-up. Instead of completely thawing the next time the walk-in warms up, the outside layer thaws and rains down on the floor and other equipment while the inside stays frozen (notice the water drops, image to the right).

As we cover in the Advancing Better Beer Course, wet insulation is like skiing in a wet ski jacket - it doesn't work. Your line chiller is working hard to keep the ice frozen, not your beer cold. Your line chiller will run constantly, shortening its shelf life and costing you a fortune in extra electricity.

Reason # 2 - Condensation develops on the walls which turns to mould.

When warm air enters a cold fridge, condensation starts to develop in all external surfaces - see above. Yeast (always in the air) starts to develop growth...think Petri Dish.

Before you know it the walk-in walls and the line exteriors are covered with a white film, which turns to white powder, which becomes black and then green after a couple of months or so.

This becomes compounded if the fan is on-again, off-again multiple times a day, or if you forget to turn it back on after you leave.

Recently I was in a walk-in beer fridge at 3pm where the fan had been off since 10am and it was 55F. This happens a lot.

Reason #3 - When you turn off the fan the fridge warms up quickly. This causes the beer to warm in the lines that run from the keg to the top of the fridge, the jumper lines, beer in the FOB, and beer in the exposed trunk line along the wall.

To make matters worse, eventually the kegs warm up if the fan is left off long enough.

Warm beer is foamy beer and that puts added stress on your line chiller.

Line chillers are designed to keep cold beer cold, not make warm beer cold.

Warm beer in one line in the trunk bundle will warm up the other lines touching it, so you will now have three taps pouring foamy beer. Every second of foamy beer from a tap is 25 cents of beer down the drain. Yup, that's $1.00 every four seconds, for each tap.

Leave the fan on at all times and dress for the cold.

The Solution

The Serve Better Beer Course is designed for anyone who handles draught beer. It covers all of the things that have an impact on draught beer quality, profitability, and sales.

Regardless of how long you've been in the business, this course helps you understand how the "little things" (like shutting off the fan) have a massive impact on the draught you sell.

Learn:

-why you should store certain kegs upside down

-the simple trick to save you $146 per tap per year

-how to tell if your staff tap a warm keg

-much more.

Used by many independent restaurants, chains, and colleges, this course pays for itself in as little as a couple of days.

Other Training Options

In-Person Seminar

Want Steve to present live?

No problem.

Click here for In Person Seminar info

General Staff Meeting

Want to show the course at a General Staff Meeting?

No problem. Just plug a laptop into a projector or a screen and stream the course for everyone, all at once.

Click here for Streaming Seminar info

Up next...

Advancing Better Beer Course

Building on the Serve Better Beer Course, the Advancing Better Beer Course is designed for key-holders in your restaurant.

A must have for anyone who is responsible for restaurant operations, this course covers advanced level troubleshooting, detailed explanation of how the system works, and tips and techniques that you can use to help improve your quality and profitability.

Check out the Introduction video.

The industry's only online course to help you solve draught foaming and quality issues.