Line Chillers

Because Warm Beer Is Difficult To Pour

Posted: June 8, 2018 | By: Steve Riley | Time to read: 7 min

Download all of this great content in a printable guide at the bottom of the page.

People like cold beer.

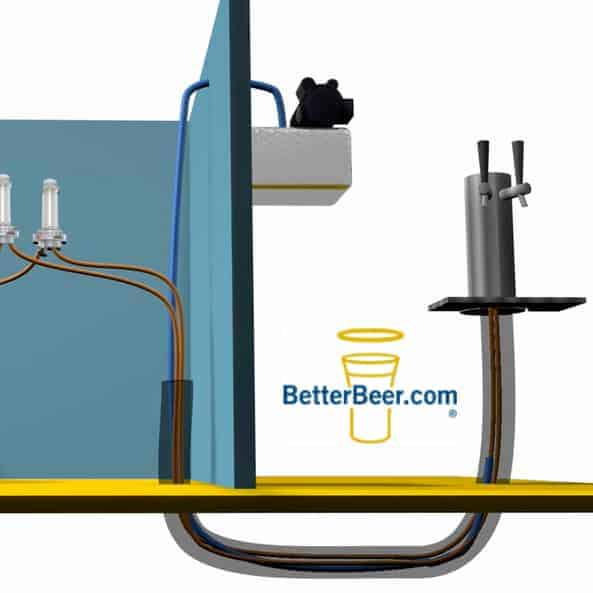

The Line Chiller (aka Power Pack or Glycol Deck) is responsible for keeping beer cold inside the trunk line.

It is important to know that the Line Chiller keeps cold beer cold, it doesn’t make warm beer cold.

The beer that enters the trunk should be cold, thus the importance of a cold walk-in fridge.

Just to be clear, cold is defined as 3°C (38°F).

Basics

The Line Chiller usually is beside the walk-in or it sits on top of the walk-in fridge. It has a compressor that cools a Glycol (liquid food grade antifreeze) and then pumps that glycol through two lines inside of the trunk.

We have covered how the chiller lines are bundled in the trunk in the Trunk Line article. (Clients - log into Resources Section to view)

The Line Chiller is made up of several components:

Polypropylene Glycol – Glycol for short, is a food grade liquid antifreeze blue or pink in colour. It comes in a concentrated form that needs to be diluted with water, usually 1:1.

Bath (A) – The glycol gets poured into the bath, which is a small tank behind the pump and motor in this deck.

Pump & Motor – the grey cylinder is the motor (B) which spins the pump (C). This is what pushes the glycol from the bath into the trunk and back into the bath.

Compressor (D) – behind the grey screen on the left of the deck is a compressor that chills the glycol in the bath.

Inside the fridge – The “U” Bend

The supply and return lines leave the deck and go into the fridge, close to where the trunk line exits the fridge.

The supply and return lines enter the trunk while it is still inside the fridge to ensure that there are no warm (or non-chilled) areas of the beer lines.

It is imperative that every inch of supply and return lines be covered in insulation so not to become covered in ice, which makes them less efficient.

Thermostat

On the front of the deck is a LED display that will show the temperature of the glycol inside the bath.

This number should be between 28 and 33.

Typically, there is a six-degree swing between the bath temperature and the tap temperature.

If the bath is at 28, the tap temp will usually be 34.

The Molson Sub Zero system and some larger, high powered systems are the exceptions to this rule, but for the most part, you are looking for 28-33 on the reading.

Common Line Chiller Issues:

Frozen Beer – The deck is too cold because someone set the thermostat that controls the temperature of the bath too low or it is broken and needs to be replaced.

The freezing typically happens at the U-bend in the fridge as this is where the supply line is the coldest. It is usually light beers or Guinness (lower alcohol %) which freeze first.

If it happens occasionally, you can trip the breaker that powers the deck leaving it off for about an hour to thaw.

However, your refrigeration tech should be called to adjust or replace the thermostat as tripping the breaker continuously isn’t good for the compressor or the motor.

Beer is Warmer Than Usual - if the temperature increase is slow to happen and is under 50° F, these could be a few reasons:

-

The screen cover in front of the compressor is matted with dust. The compressor has a fan which sucks in air to help the compressor from overheating. If the screen becomes matted with dust, the compressor chokes and warms up, making it less efficient, and it cannot cool the bath effectively.

-

The glycol is evaporating and there is less in the bath. Because the return glycol is slightly warmer, it warms the bath slightly. The less liquid in the bath, the longer it takes the bath to recover making it warmer and warmer. Think of global warming on a much smaller scale. Ensure your deck is checked every few months to ensure a good fill level of glycol.

-

The glycol is frozen – if the lid that seals the bath is not on tight or has some gaps in the insulation, warm air gets in causing condensation on the inside of the lid, which drips into the bath. As the bath fills with condensation, the liquid overfill spills out the side. Over time, there is less and less glycol in the bath and more water. Since water freezes at 32° F and the chiller is set at 28° F, the water freezes and there is less liquid to pump through the lines.

-

Using store-bought glycol. Not all glycols are created equally. To save a few bucks, people have used glycol that is designed to put in your cottage plumbing to keep it from freezing. This glycol is not designed to be in motion and easily separates from the water causing the water to freeze. Less water means less liquid to pump and slower recovery times.

Warm beer – if all of the beer is pouring warm, over 50° F:

-

The breaker in the electrical panel has tripped so no power is going to the deck.

-

The motor is burned out and isn’t powering the pump.

-

The compressor is burned out and isn’t chilling the bath.

-

The deck is completely out of glycol, or the glycol is frozen solid. Both of these quickly burn out the motor.

Like this article? Request access to our Insider's Series which is packed with great info like this to help you improve draught quality, profitability, and sales. Oh, it's FREE to sign up.

Best practices:

-

The deck should be in an area with good circulation. While above the fridge is out of the way, sometimes there are other compressors (which create heat) up there so the area gets very hot. Installing a fan helps. Closing in the space above the fridge does not help.

-

Do not put the deck inside of the walk-in. While this may seem like a good idea to keep the glycol cool, it doesn’t help as the compressor creates heat when making the glycol cold, which warms up the walk-in.

-

Insulation is our friend. All glycol lines must be completely insulated. Also, the inside of the lid should have a small strip of foam insulation around the edge to create a seal with the bath sides to keep warm air out.

-

The compressor screen should be cleaned every month or so by brushing off the dust with your hand and then spraying with the water sprayer in the dish pit. Allow the screen to air dry before placing back onto the front of the deck.

-

Long lines/large number of lines should have more than one deck. In an establishment with more than 25 lines, there should be at least two pumps and motors from one large deck or two separate decks.

-

Use glycol designed for draught systems.