Draught Beer Predictions - 2019

Time to read: 6 min | By: Steve Riley | January 6, 2019

#1 - Non-alcoholic Beer On Tap

Non-alcoholic beer will get a tap listing. Sales are improving, it is becoming more socially acceptable, and most importantly - it doesn't suck any longer!

Let's face it, up until a couple of years ago, it wasn't very good. Now that's all changed.

It will take a relatively large chain to make the leap and add it on tap. The licencee who takes that leap will be mainly concerned with ensuring that they can secure a steady supply. They'll test it for 3 months and see what kind of feedback they get.

If someone asked us our opinion - we'd suggest that they put two on tap. A well-known, mainstream brand like Budweiser Prohibition Brew, Heineken 0.0, or Coors Edge. And a flavourful beer, like Partake Pale or their IPA. This way you cover your bases with mainstream consumers as well as those who prefer a more flavourful beer.

With an aging demographic, tougher impaired driving laws, an increase in healthy living, this seems like a lock as far as we're concerned. ABI believes that 20 percent of the world’s beer production volume will be non-alcoholic or low alcoholic by 2025.

Who will be the first to make the leap?

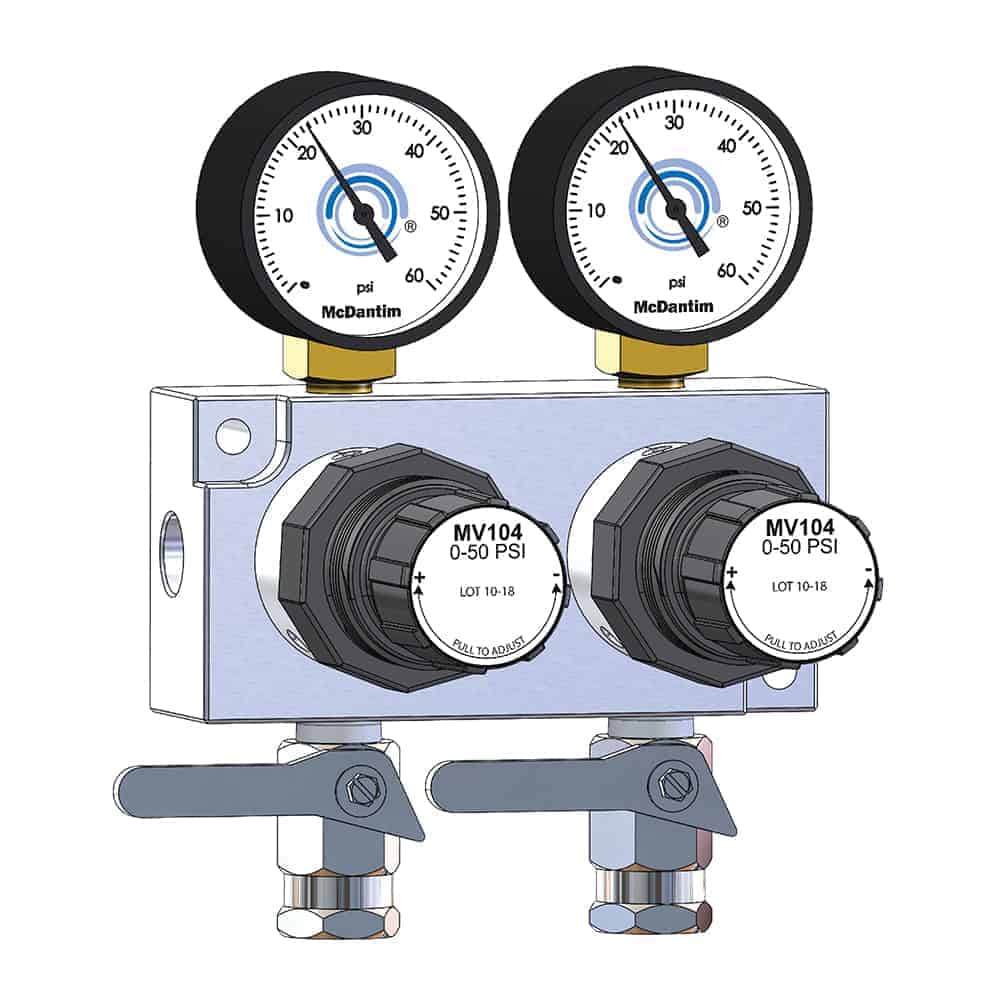

#2 - Better Gas Regulators

The good beer gas folks over at McDantim released a very interesting report in Nov 2018.

Like many of us, they have been stumped by the occasional mysterious inconsistency in draught beer issues - when everything seemed to be set up correctly, but there were still foaming issues. WTF?

The issue? A lack of hydraulic pressure consistency. What is that you ask? Good question.

The ability of a regulator to maintain its set pressure under the constantly changing flow requirements is exactly what a perfectly functioning draught system requires.

When there is inconsistent pressure, we get a de-gasing of the keg which causes FOB drops and pockets of foam in the line.

So they put on their propeller hats and went to the lab to do some testing. They ran several tests, but the two we found most interesting were the pressure drop vs # of taps open and the slow bar overnight testing.

What did they find? Almost all of the regulators tested failed in some capacity.

We need better secondary gas regulators and we believe that we'll see improvements and a focus on them in 2019. Two new ones to watch - TruReg from McDantim and the GovReg.

We've got a couple of the GovRegs in some of our client's walk-ins now to test them and we'll provide feedback once testing is complete.

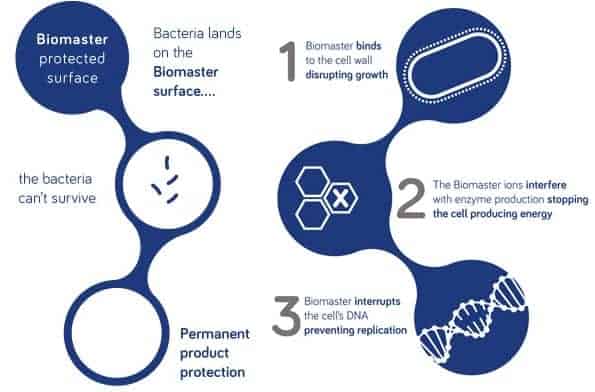

#3 - Anti-bacterial Beer Lines

Trunk lines upgraded years ago with the release of barrier style tubing, a smooth, glass-like interior that helped reduce build-up.

The challenge has always been with controlling build-up in the jumper lines (keg to FOB) and choker lines (trunk to faucet) since those lines are more pliable.

I think this is about to change. By adding silver ion to the lines, it stops growth from developing inside the lines.

We're not sure the effect this will have on beer, but it is being used in other food service applications. NewAge Industries of SouthHampton Pennsylvania is currently testing and selling their Clearflo Ag-47 (symbol for silver on periodic table) Antimicrobial Tubing.

Jumper lines are rarely changed as frequently as they should be. They are usually permeated with beer and they are one of the first signs of improper line cleaning. Improving jumper line quality will have a huge impact on overall draught quality.

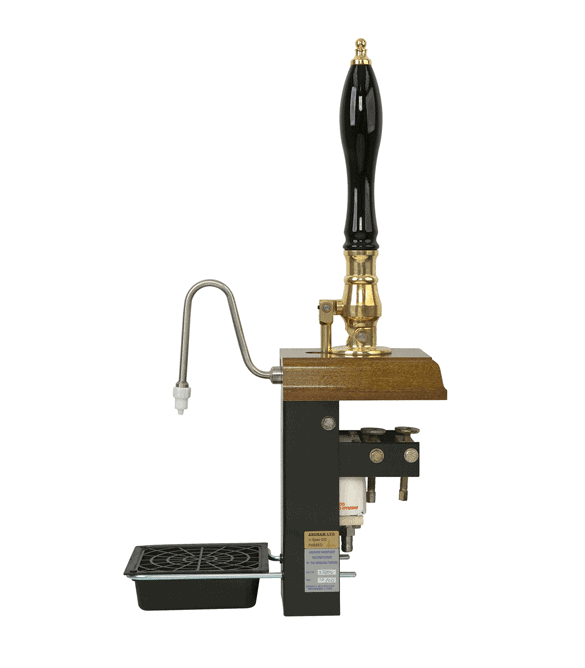

#4 - Cask Will Gain Popularity

I've spoken to several people about this in the past few months and although there are differing opinions, I believe that we'll start to see cask gain some popularity.

With the explosion of micros, competition is fierce and they need more places to sell their beer; on-premise is a perfect place to get people to try your beer.

Yes, cask is already in a few places in most cities, but it is limited to beer-focused, independent bars. There is exposure at chains and exposure is what brewers need.

Some challenges to cask: few staff know to handle cask, it has a 3-day shelf life, and the public's impression is that it is "warm and flat".

But people's tastes and understanding about beer are changing. Ten years ago there weren't as many flavourful beers on the market. Now it is flooded.

Here's how to make it work: Cask beer handling training for hospitality staff, scarcity (one-night only), and local. Like non-alcoholic beers (see prediction 1) it will take a chain with the right beer culture to make it work. One night a week or month they host a cask night with a hyper local brewery's beer on cask. The brewery folks must attend and chat with the guests. And it needs to be promoted.

It's not if it will happen, but when it will happen.

#5 - Line Cleaning Solution

As they say, last but certainly not least...

There will be an increased focus on what brand / type / quality of line cleaning solution that techs are using when they clean lines.

Not all cleaning solutions are created equal, and we have seen first hand how the quality of the cleaning solution affects the quality of the beer.

In 2018 we saw the first cleaning solution being imported into Canada from the UK. If a foreign manufacture wanted to sell more, they should look at the Canadian market, because the choices here are slim and to be frank, not great.

Things to look for: better technology and science behind them as a point of difference, colour changing solution which shows clean vs dirty, and a solution that is highly concentrated to keep price per usable ounce lower.

A smart line cleaning company owner would source the best solution and use that as a point of difference over their competitor.

Using powder-based, no-rinse cleaners on commercial systems is a joke and those days are coming to an end fast.