How BetterBeer.com Helps

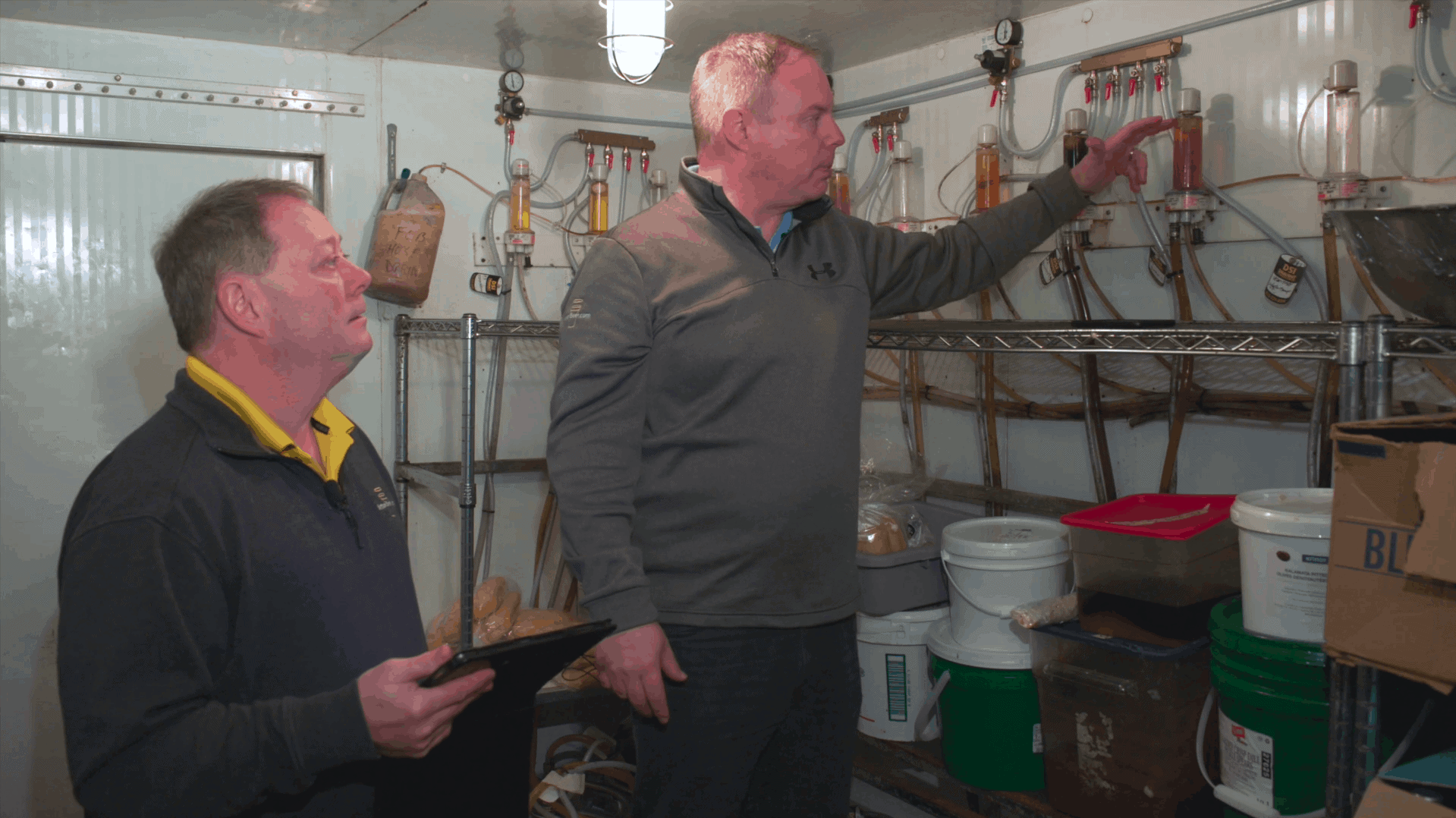

Draught Quality Assessments

Why do you need monthly checks if you have a draught service company?

- Draught Service companies clean and service lines (we do not).

- They are reactive, meaning that they fix broken equipment when it breaks.

- They don't proactively check your system to find potential issues BEFORE they happen.

- They don't check temperatures, date codes, proper rotation, beer glass cleanliness, or signs that your staff are doing what they should do.

- And they certainly don't tell you that they missed a thing or two when cleaning your system.

This is where we help you where others can't.

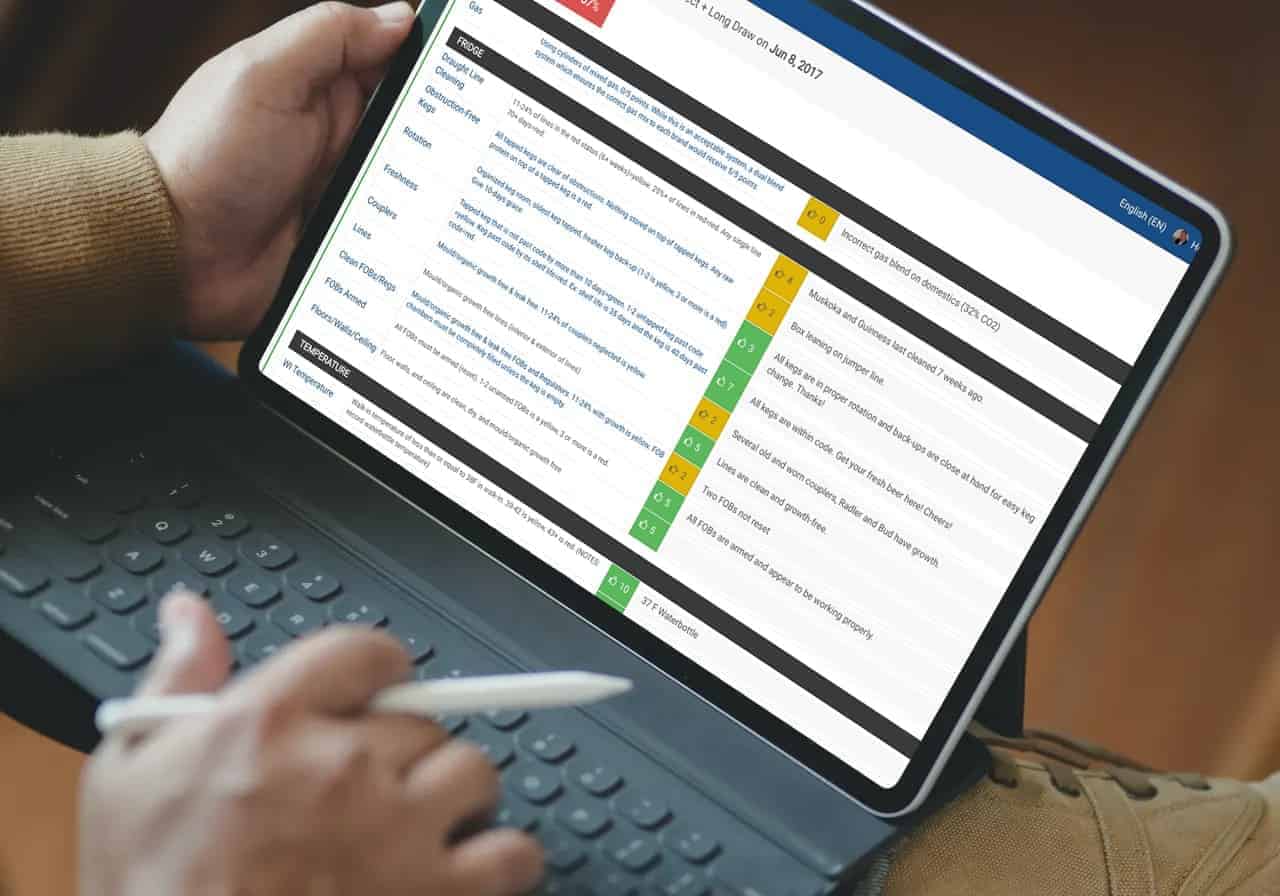

What do we check?

- Line cleaning frequency and quality.

- Date codes on kegs to ensure proper rotation and freshness.

- Temperatures of walk-in and beer from the tap from each trunk line.

- Over twenty quality checks per line.

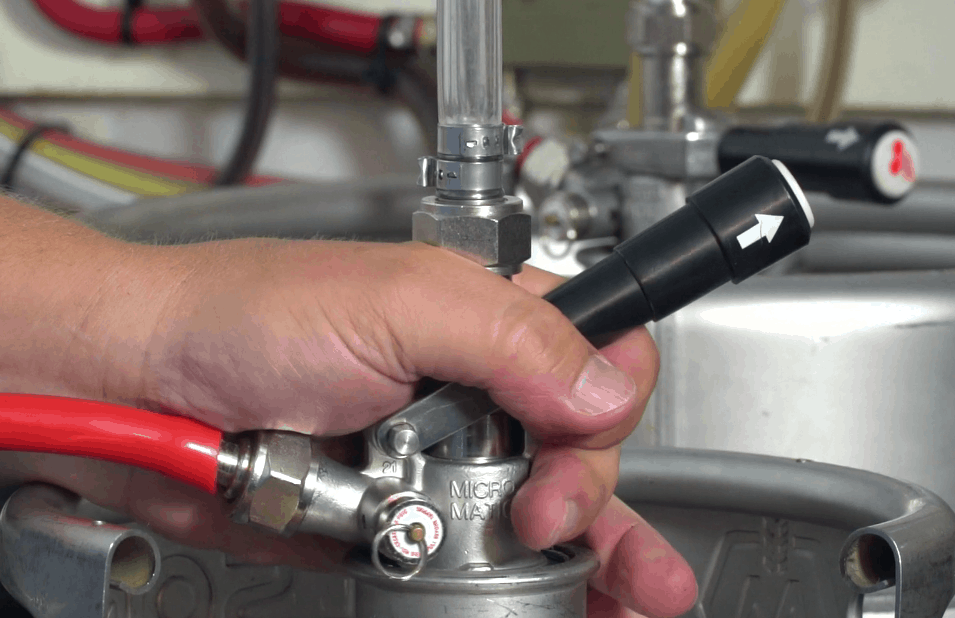

- Condition of the towers, lines, couplers, faucets, and FOBs.

- Plus much more

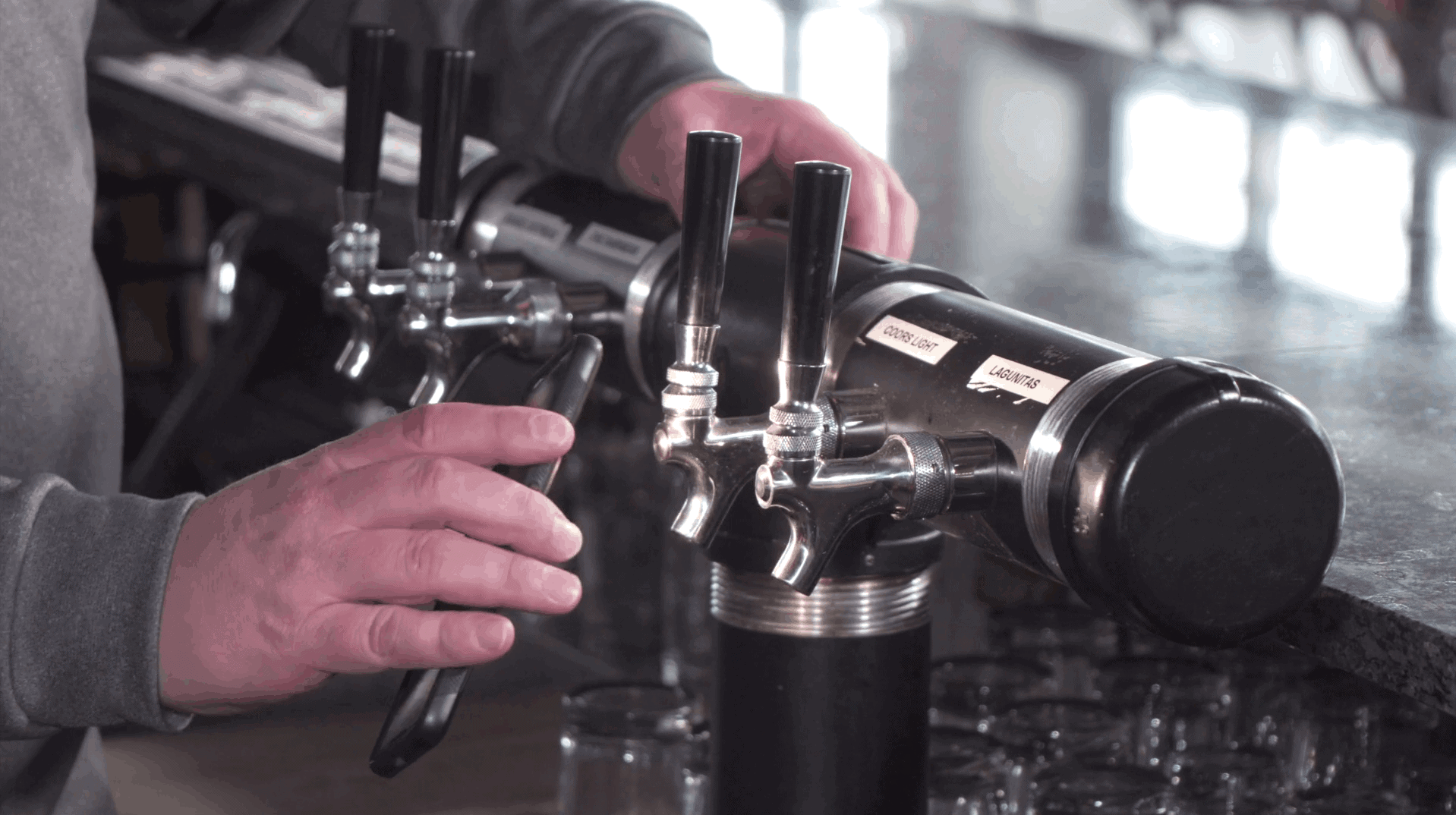

Dirty Beer Glasses

The biggest issue in the industry. They cause:

- lower re-order rates,

- flat-looking pints,

- over-pours,

- returned/comped pints.

Use our Beer Glass Cleaning Kit once per week to supplement your current glass cleaning.

In only 20 minutes per week, you can make a massive improvement in your draught quality.

Here is a video on how to tell if your glasses are clean, what causes them to be dirty, and how to fix it.

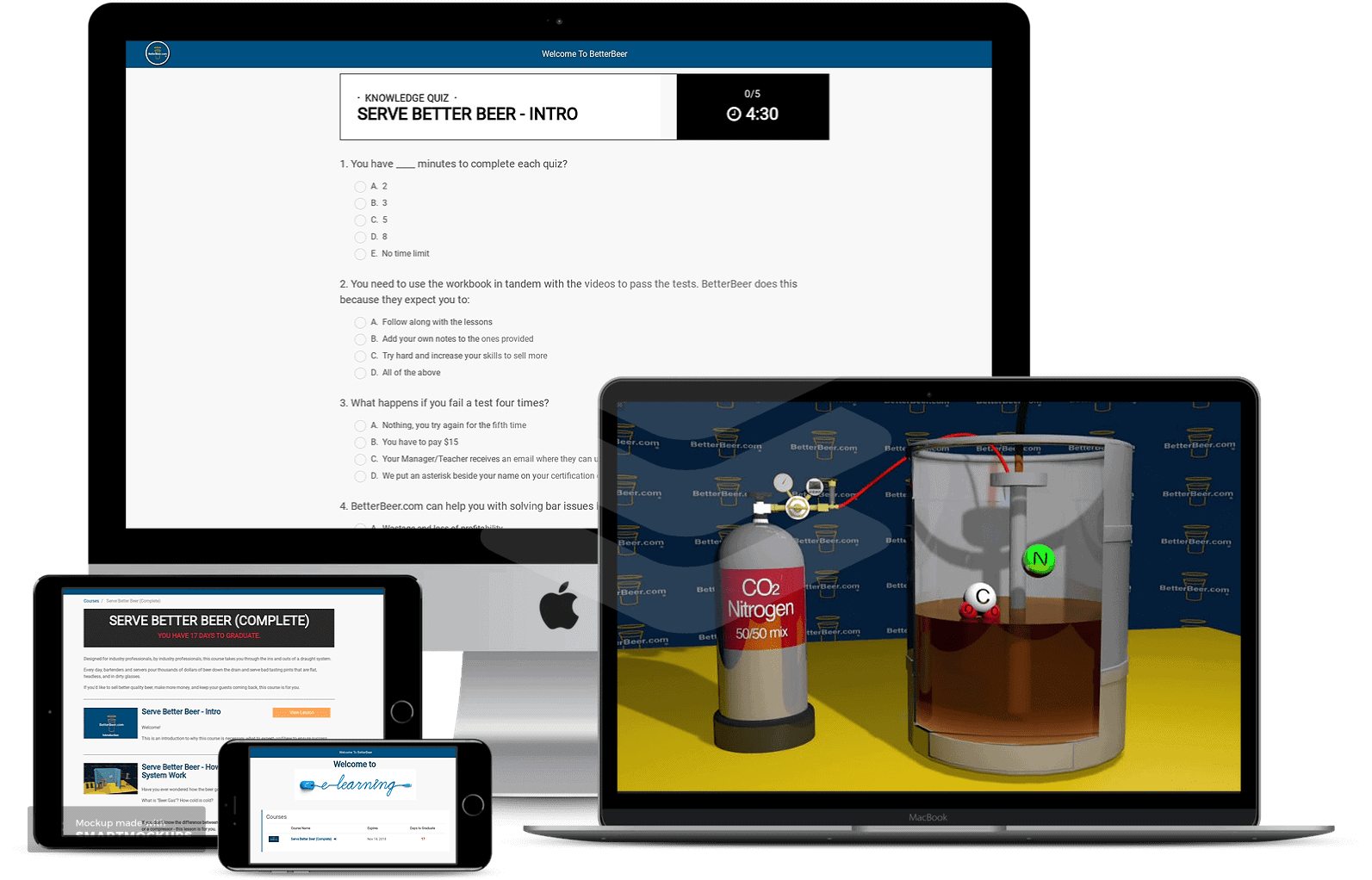

Draught Quality Training

Online, trackable, and informative.

Two levels of courses: Serve Better Beer for anyone who handles anything draught related.

- How the system works – what are regulators, couplers, faucets, and FOBs.

- Proper storage and receiving of kegs – which kegs should you store upside down?

- How to change a keg without getting a beer shower.

- Proper pour – You’ve told them to put a head on the beer, but we tell them why.

- Beer clean glasses – when your staff understand what Beer Clean Glasses are, you make more money.

- Branded glasses – yup, they’re a pain, but they also make your life much easier, and you make more by using them.

- Using FOBs – not knowing how to use a FOB properly will waste $6 of beer at EVERY keg change.

- Troubleshooting – the system only breaks down on busy nights it seems. Wouldn’t it be great if you could solve some problems on your own and get back to selling pints?

- And…how to sell more beer.

Advancing Better Beer for Keyholders/Managers. More technical with a greater focus on troubleshooting.

- Beer gas - cylinders vs blender.

- Understanding Line cleaning - what should be done each month.

- Glass rinsers - how they work

- Jumping kegs - why you shouldn't.

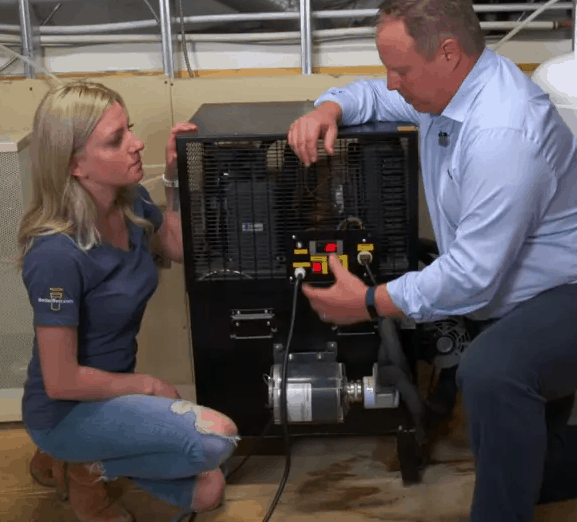

- Line Chillers - how to troubleshoot warm beer.

- Trunk lines - often neglected.

- Plus much more...

Both courses are about 90 min each.

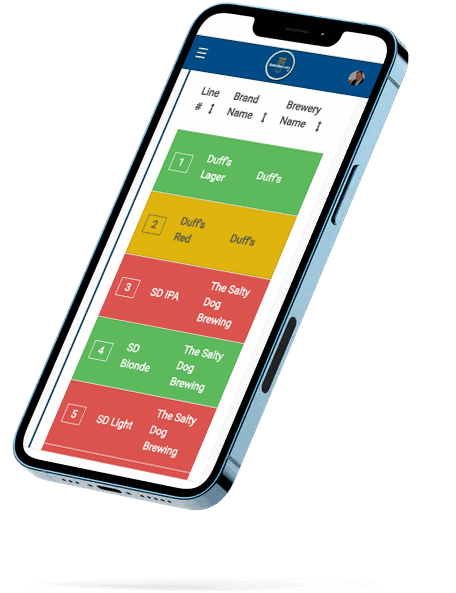

Beer Line Cleaning Tracking

Most operators can't say for certain when their draught lines were cleaned last. Our online draught line cleaning tracking program, Tap Trackers, will help you ensure your lines are being cleaned when they should be.

Know when your lines were last cleaned, which type of clean (there are two types), and who cleaned them.

The retail value of this program is $3,360 per year.

Your Better Beer Full Program includes:

- 12 monthly draught quality assurance assessments.

- one commercial-grade beer glass cleaning kit with a two-year. supply of glass cleaning tablets.

- full use of Tap Trackers - the online beer line cleaning tracking software.

- 10 passcodes to the Serve Better Beer course.

- 10 passcodes to the Advancing Better Beer course.

- Access to our online library of draught resources - videos, manuals and articles. The largest collection of such information in the world.

- A trusted advisor who you can contact with any draught related questions or concerns. Useful if you are being told something draught related that you are unsure about.