Do Your Line Cleaner A Favour

Keeping your draught system clean is a team effort.

Being a Draught Service Technician is a difficult job.

Compared to other trades, they are underpaid, especially for all the work they do.

Most of the time, the only recognition they get is when they come in for a service call and save the day to get your draught pouring again. And usually, that recognition is from your regulars cheering about how “The Beer Guy saved the day!” That makes them feel like they are making a difference. Who doesn’t like that?

Here’s the problem – you may be making it difficult for your line cleaner to do their job.

Line cleaning is like a parade.

Cleanings are scheduled sequentially, so if a cleaner has 50 establishments to clean each cycle, they do them in order because, logistically, that's more efficient.

When the cleaner can't get in on their regular scheduled cleaning, the parade gets backed up.

Here’s how you are causing the parade to back up:

-

They show up at 8am when your KM is usually in, but the KM is 30 (or more) minutes late.

-

The KM / Prep Cook doesn’t have the beer fridge keys.

-

The bar isn’t tidy, so they have to spend a few minutes cleaning up so they can do their job.

-

The produce order is stacked in front of the beer fridge door, so they have to move it.

-

The mop sink is full of garbage cans, bar mats, and buckets full of dirty rags – they can’t fill their cleaning pots with water.

And here is the biggest issue – you have bus tubs and boxes of food on top of the kegs.

This presents a MASSIVE challenge. What the heck are they to do with a bus tub of raw protein or lettuce or beer pitchers of BBQ sauce/salad dressing, or cases of bottled beer, or …..

-

They're in trouble if they put it on the walk-in floor and the health inspector comes in.

-

If they accidentally knock over a container of food, they're in trouble.

-

If they knock over a case of beer (or the bottom falls out from being wet) and the bottles break...trouble.

-

If they put a bus tub of raw protein on a shelf above a shelf of raw vegetables and the health inspector comes in...big trouble.

-

If they spill anything on the floor or the kegs, they have to clean it up.

We understand why you have to store boxes and bus tubs on top of kegs.

It happens because some people who design restaurants have never worked in a restaurant. They are trying to squeeze in extra seats in the FOH, and that square foot has to come from somewhere.

Also, building one large walk-in is cheaper than building two. So they amalgamate the walk-ins – beer and food in one. Looks good on paper. But it is not in real life.

So here’s what you need to do:

-

Make sure there is someone there when they should be (8:00 am?) and who has the keys to the beer fridge.

-

At closing each night, make sure the bar is clean and tidy, the mop sink and walk-in is accessible.

-

Put orders away when they arrive, don’t use the kegs as temporary shelving – for ANYTHING.

-

If you can ensure someone is there with keys before 8am, let your draught service company know – they can get in as early as you can; the earlier the better for them.

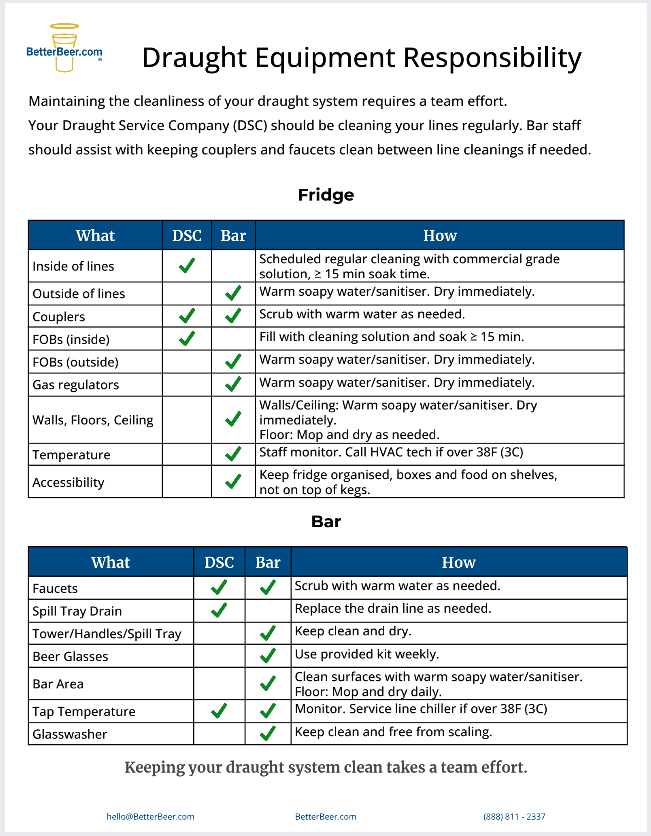

The outside of the draught system components should be cleaned by the bar.

The inside of the components are usually cleaned by the line cleaners.

Bar staff should clean the couplers and faucets between line cleanings if needed. Use a toothbrush, warm soapy water, and a little elbow grease.

A clean draught system is a team effort.

This document outlines who is responsible for each component of the system.