What You Need To Know About Line Cleaning

My goal with this post is not to steer you away from enjoying your pints.

The last thing I want is for you to think that you should stop drinking draught.

Our company mission is to increase draught quality, profitability, and sales - not to have you switch to bottles.

But, this needs to be discussed.

Your bar needs to be on a regular line cleaning program.

Period, no discussion, no hesitation.

Yes, there is a cost, but look at beer line cleaning as an investment, not a cost.

Why you should clean your beer lines:

In simple terms, dirty lines are caused by “Beer stone” developing inside of the lines and equipment.

These beer stones are little calcium deposits (beer contains calcium) that look like grains of sand.

Beer also contains yeast that attaches itself to this beer stone.

Over time, yeast will create Diacetyl (pronounced: die-ass-ah-tall) which gives the beer a buttery taste and a slick mouthfeel.

If your beer tastes like butter and it feels like you are eating a Werther's candy, it is usually from dirty draught lines.

It won’t kill you, but it gives you an exaggerated hangover and an upset stomach; you’ll feel like you had ten pints, but only had two.

Like this article? Request access to our Insider's Series which is packed with great info like this to help you improve draught quality, profitability, and sales. Oh, it's FREE to sign up.

Who should clean your beer lines?

Line cleaning should be done by a Draught Service Technician, who has insurance, training, and the correct equipment.

Every city has several of these companies. Unfortunately, every city also has several companies who claim to clean lines but don't have insurance, training, or the correct equipment.

How do they clean draft lines?

They should be using a commercial-grade cleaning solution that is only sold to professionals.

Bleach, baking soda, vinegar, or anything that you can buy won't cut it.

This isn't a kegerator in Joe Public's basement they're cleaning, it's a complicated system in a bar.

It should take at least an hour to clean ten lines and cost about $12-15 per line. You get what you pay for.

When should I clean my beer lines?

How long is a piece of string? It depends. Same answer with line cleaning.

A regular line cleaning program can mean many things.

In our experience, as long as the cleaning is kept up, they are following industry standards, using a commercial cleaning solution correctly, your lines are relatively new (≤ ten yrs old), and kept cold - you can go every month.

If your trunk lines are old and warm, you are probably looking at a weekly cycle instead.

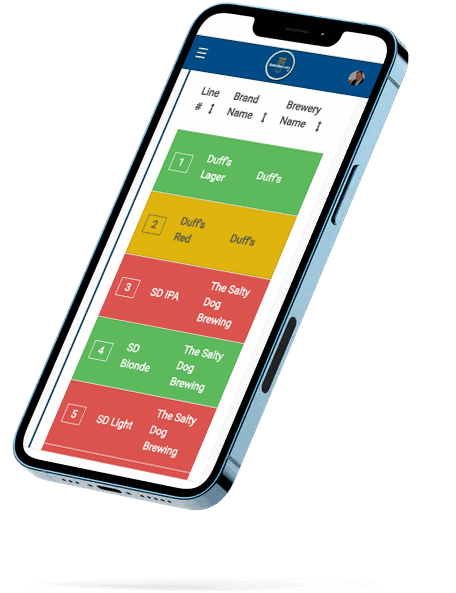

If you clean beer lines or operate a restaurant that has more than one line cleaner, you need to subscribe to Tap Trackers.

An Inexpensive, Easy To Use, On-Line Solution For Tracking Beer Line Cleaning.

Tap Trackers helps beer line cleaning companies improve frequency,

profitability, & customer value.

Like this article? Request access to our Insider's Series which is packed with great info like this to help you improve draught quality, profitability, and sales. Oh, it's FREE to sign up.

Things to think about when it comes to beer line cleaning:

Yes, you will lose the beer that is in the line each time the lines are cleaned. There is no way of capturing that beer and re-packing into the lines. I used to own a draught service company, and I spent a considerable amount of time with engineers and inventors trying to figure out that puzzle and you can't. Believe me, if there was a way the Health Board would allow the beer to be captured and sold, I'd have a patent by now.

At ten cents an ounce and about a half ounce per foot, if you have a 60' run, you are losing about $3 per line each line clean. (60 x 0.5) x 0.10 = 3.00

So if you have ten lines, it's $130 per month for the service and lost beer; $1,560 per year in line cleaning.

If you don't make that investment, then:

- your draught sales will drop

- people will switch to bottled beer (less margin) or water (no margin)

- feel sick from drinking bad draught and blame your food, or never return.

If you sell ten kegs a week at $6 per pint and 100 pints per keg, you gross 6k a week, or 312k per yr from draught sales.

That $1,560 is 0.005% of total draught sales.

Or, look at it this way - 10 kegs per week at 100 pints per is 52,000 pints a year.

Split that $1,560 by 52k pints and it costs you an extra 3 cents a pint. Three cents.

Put your prices up a nickel to pay for line cleaning and put an extra grand in your jeans each year at the same time. A nickel. That's how easy it is.