Better Beer Insiders

The industry-only, invite-only group that helps you pour and sell Better Beer.

Limited Spots Available.

Once they are gone, the door closes.

Once they are gone, the door closes.

In This Email Series, YOU Will Discover:

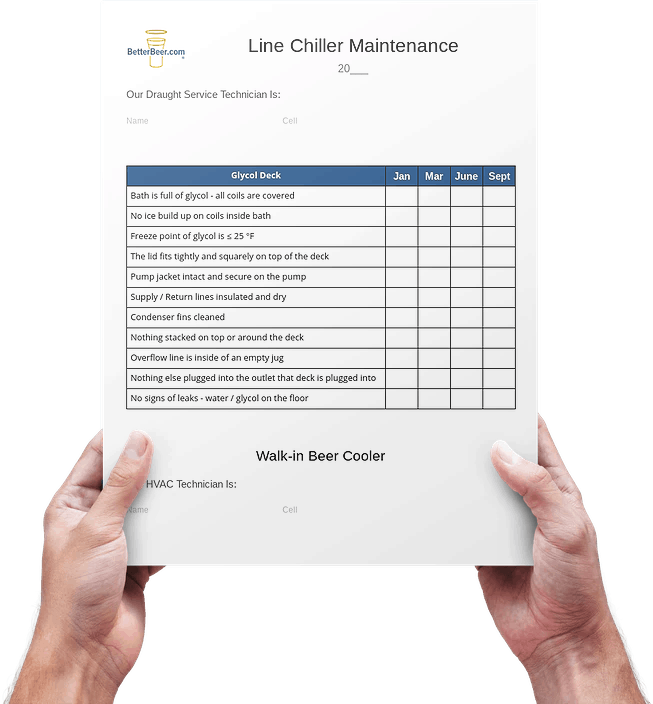

How to avoid selling warm beer - Line Chiller Maintenance Checklist (you'll get this checklist as soon as you sign up)

How to avoid the 3 Line Cleaning Issues That Cost You Thousands.

Tips to stop pouring foamy beer.

Why you shouldn’t shut the gas off each night like some "experts" say you should

Tips to avoid selling old, past code beer, & connecting kegs to the wrong lines.

How temperature impacts proper pour. Yes, your beer can be too cold.

How to stop discounting your pints.

The solution to the industry’s biggest problem - dirty beer glasses.

And much, much more.

You probably fall into one of these three categories:

-

You struggle with your draught system - it rarely pours properly and you usually experience draught variance between 10-15%.

-

Your draught system occasionally becomes foamy and you have the odd pint returned by a guest. Your draught spillage can vary from 5-10%, depending on the week.

-

You keep your draught variance under three points but you know deep down that you could do better. And you think that your competitor may pour a better pint than you, but you’d never admit it.

When I was in the restaurant business, I was always in that first category. “Ten per cent draught spillage is normal, it is just a cost of doing business,” I thought.

Then I started learning about draught systems.

I realized that there are only two possible causes of draught spillage - your system or your staff.

The content and systems we've created over the past ten years has helped every kind of restaurant/bar owner/operator improve their draught quality, profitability, and sales.

And we're going to share this incredible content with you FOR FREE

What's the catch?

There is none.

Occasionally we'll tell you about some of our services that will help you and we'll extend an incredible offer that you won't see anywhere but here, but you never have to invest in us if you choose.

Cheers,

Steve Riley

President, BetterBeer.com Ltd.

Do NOT share this page!

You have been hand-selected to join this group.

Please do not share this page with others.

You have been hand-selected to join this group.

Please do not share this page with others.

You know that you can benefit from the extremely valuable content we are offering to help you improve your draught quality, profitability, and sales.

It is FREE to join. Simply fill out the form and start receiving valuable Insiders information in your inbox today.

Boom! Too easy.

FREE - Line Chiller Maintenance Checklist

Warm Beer Sucks

Make sure that your glycol deck keeps running so your beer stays cold.

Download our Line Chiller Maintenance Checklist and post it near your walk-in. Once a quarter, have your service tech go through the list.

Because people like cold beer!

Protect Your Bar From Selling Warm BeerSign up and get instant access to the checklist.